20. REACTIVE AND NON-REACTIVE STEELS, WELDED TOGETHER

20. REACTIVE AND NON-REACTIVE STEELS, WELDED TOGETHER

What is this?

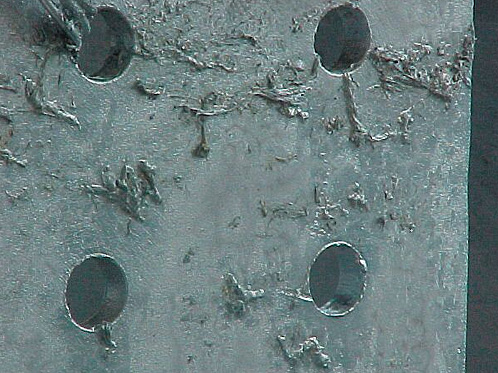

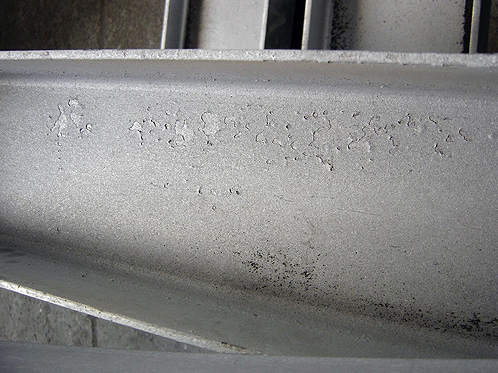

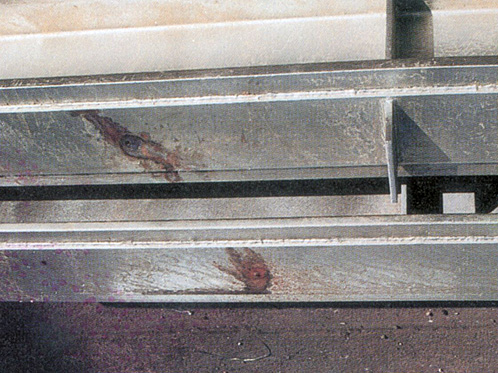

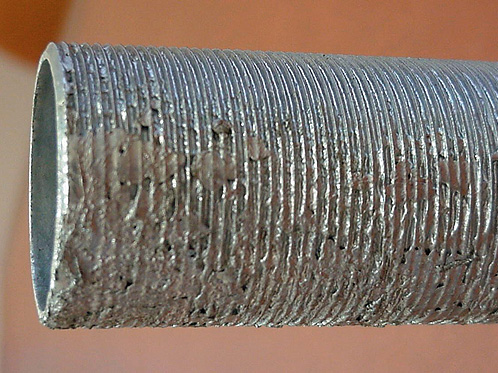

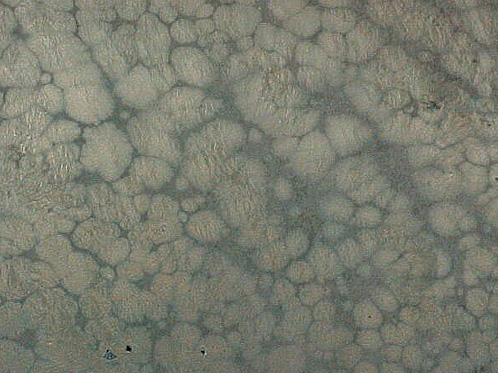

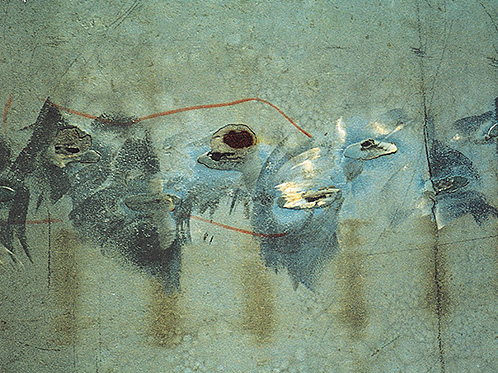

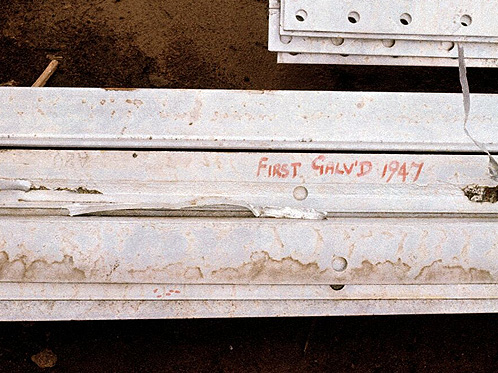

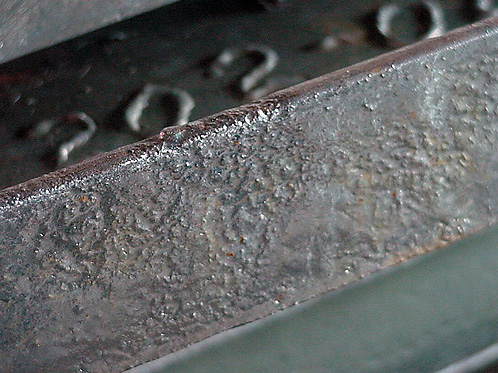

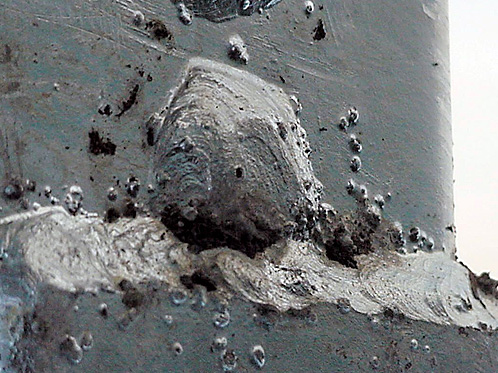

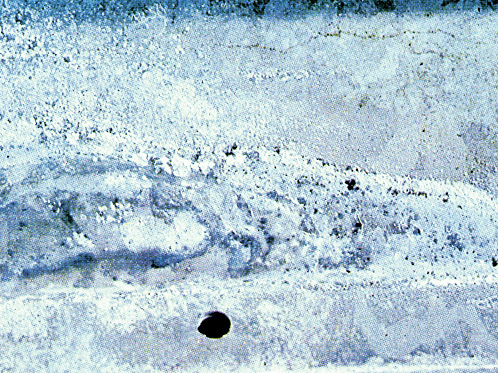

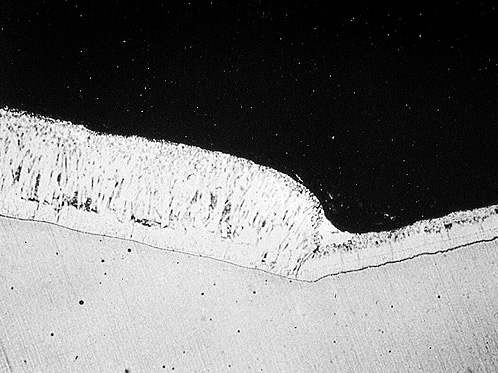

Variations in coating thicknesses can arise when reactive and non-reactive steels are welded together. Efforts to increase coating thickness on the less reactive steel may result in an undesirably thick and brittle coating on the most reactive steel.

Cause

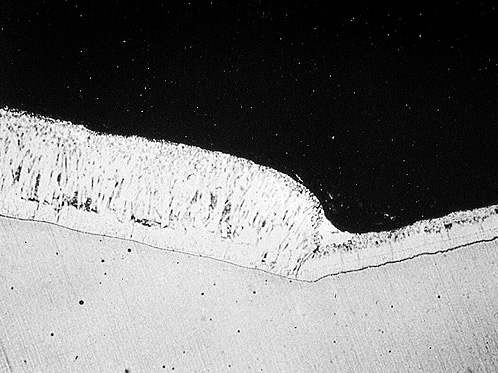

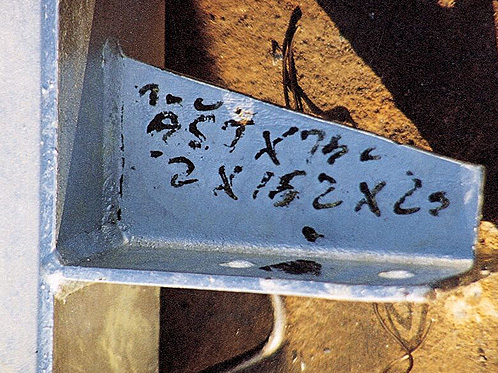

This difference in coating thickness is brought about by a combination of a more reactive silicon killed steel and / or high phosphorus, resulting in a thicker coating and a less reactive aluminium killed steel, resulting in a coating thickness sometimes below that required in the specification.

Should the galvanizer be asked to regalvanize in accordance with the specification, the resultant coating thickness on the reactive steel will be excessively thick, resulting in a brittle coating more susceptible to damage.

Effect / Remedy / Responsibility

The fabricator should select the same steel for fabricating on a component.

If need be, accept a concession request by the galvanizer when the thinner coating is possibly below specification.

| T: +27 (0)10 746 8927 | E: hdgasa@icon.co.za

| T: +27 (0)10 746 8927 | E: hdgasa@icon.co.za